The crash helmet game is changing. The most simple, most obvious form of motorcycling safety has progressed from leather ‘skull caps’ as little as seventy years ago to the kind of material composite and ‘suspension’ technology perhaps more advanced than the equipment found on the bikes themselves.

In the past companies large and small, specialised and speculative have fabricated their own ideas of protection and performance adhering to the DOT, Snell and ECE tests and criteria for impact resistance and strength. The development of shell materials, EPS liners and internal weaves have allowed brands to further address issues connected with concussion and the potential fatal consequences of brain injury, such as rotational acceleration (where the brain essentially shears away from its roots). It is a subject we’ve looked into thanks to OTOR’s contacts with firms like 6D Helmets and then other procrastinators like Leatt and MIPS.

While a helmet with added safety specs is a boon for street or off-road riders, the additional advantages compared to normal ‘light, tested, ventilated’ units were largely ‘take it or leave it’. The vast helmet industry offered a mammoth spectrum of price, efficiency, design and innovation.

Over the last half decade and in response to the growing advances in ‘lid’ health funcionality, a proactive invesitgation and stance by the FIM – controllers of world championship motorcycle racing – has stirred the pot. The governing body sought a new test protocol to define a fresh standard of safety for every motorcycle racer that takes to a grid, gate or timing line. The FIM Racing Homologation Programme for helmets (known as FRHPhe) was a first bold move considering the sheer scale of the multi-national businesses – many of whom are steeped in history, knowledge and established manufacturing processes – would be affected. Motorcycle racing is one of the largest promotional windows for related products and the FRHPhe has already been implemented in road racing (off-road is coming) with a raft of press releases over the last six months informing the media and public of the latest model or company to pass the new control.

Not only is FRHPhe a delicate and problematic scheme for the FIM (where they had previously diverted to existing international standards for approval in their competitions) but it is also brave and exhaustive. “The process of defining the testing protocol took approximately two years,” reveals the FIM’s Erica Manfredi. “Many meetings were organised between FIM, the industry, the testing laboratories and other stakeholders. A testing protocol was published in 2017 with pass/fail criteria corresponding to a phase 1. A phase 2 has already been announced with more stringent criteria and the potential evolutions are under discussion. The helmet testing is carried out in laboratories approved by FIM. So far there is one at the University of Zaragoza and two more will be added for the near future.”

“It is difficult to give numbers as applications and tests are still ongoing,” she adds concerning the workload. “The majority of helmet brands with products used for motorcycle competition have worked hard and have had at least one model FIM-homologated in all or some sizes.”

Unsurprisingly the FRHPhe has been met with varying levels of enthusiasm/opposition, which begs the question: why do it? The FIM have overseen other strides in motorcycling competition safety, ranging from stipulations over circuit’s medical facilities and resources to minor regulations such as the compulsory use of chest protectors in Grand Prix motocross. FRHP had its next target. “FRHPhe was established in order to take account of a more complete and demanding evaluation of performance, and give specific and exclusive recognition to helmets that meet more demanding criteria,” Manfredi states. “Of course the FIM was aware that the implementation of an FIM Helmet Standard would be an uphill struggle, but believed that the key to its success was to work directly with the industry and with experts in the field of helmet testing and to establish a solid and robust testing protocol.”

For a section of the industry – those motivated by the same progressive attitude as the FIM as to what head protection can offer – FRHPhe was like another (larger) star on the banner. The road racing homologation process is well underway but off-road (motocross, supercross, rally and enduro) is awaiting finalisation.

It’s mystifying why off-road specialists are stretching ahead of their road counterparts for the performance aspects of helmets. Road lids traditionally have a preoccupation with shell strength and aside from innovations like the quick release system have evolved their products in terms of comfort (noise, visibility, fit, aerodynamics, cooling), structure (two-piece hinged full-face) and other minor technical adds-on such as Bluetooth compatibility. Off-road helmets are perhaps more rudimentary but can be even more complex when it comes to design and are far more likely to wear or suffer damage/a crash.

Ironically for the first results of FRHPhe it is the road helmets that are receiving the FIM stamp while the technologies (or idiosyncrasies) of off-road have still to be verified for world championship contests.

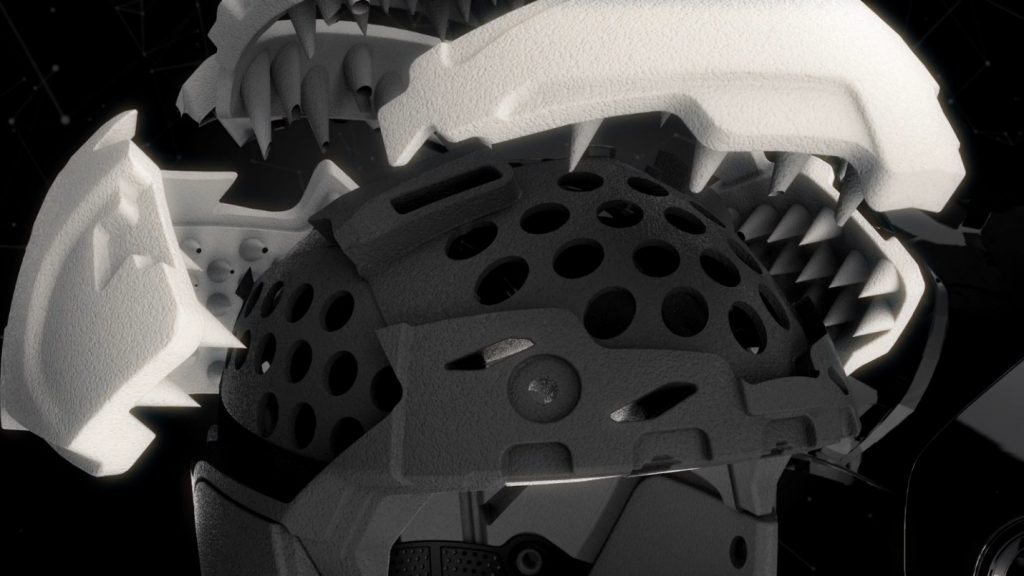

Since Californian pioneers 6D introduced their ATR-1 (the ATS being the street model and the firm have since expanded into cycling) and the Omni-Directional Suspension – a ‘damper’ system between the liners – at the turn of the decade it has prompted renewed thinking about how the energy of a crash or impact at low, mid and high velocity can be better managed. Their efforts, testing and unique (and costly but successful) manufacturing drew attention to similar philosophies, such as the Swedish MIPS mechanism (licenced and used by firms such as Fox Racing, Answer and Troy Lee Designs), Leatt’s turbine idea, Bell’s Flex and Fly Racing’s Adaptive Impact System.

6D’s Bob Weber explains that the FIM still need to refine FRHPhe for a different sport. “The implementation of the FIM’s FRHPhe testing for off-road would be a step in the correct direction, assuming that the test was modified for off-road type crashes, which will require lower impact velocities for starters,” he says. ‘The addition for rotational energy management testing will bring the safety for riders up, even at phase one for a starting point opposed to doing nothing.’

‘It is pretty amazing that the FIM has been able to make a decision, put in the work into developing a testing protocol and get many helmet manufacturers onboard to a new test standard,’ Weber adds. ‘Erica and her team had an uphill battle with some of the helmet companies in the manufacturer’s consortium to make the needed changes. For 6D this was not as hard as we have already completed the work and only needed to raise the impact velocities for our testing parameters… and spend a lot of money in doing so to meet the new standard.’

Leatt, helmed by South Africa Dr Chris Leatt who founded and developed the neck brace, claim that the Capetown-based operation have added the latest helmet test equipment to their comprehensive laboratory. Their GPX 6.5 (and 5.5) models was the result, with the Turbine Technology advocating 30% less head impact at concussion level and a 40% reduction for rotational acceleration. All the preposition and discovery through millions of dollars and years of studying motorcycle crashes for their neck brace research allows some special understanding when it comes to their work on helmets.

“The ‘best practices’ test methodology on rotational acceleration is still work in progress and there is a healthy debate on this matter within the helmet community and FIM,” he says. “We believe that test standards should be revised to include rotational type testing, as well as other test methods that would help evaluate the helmet’s ability to mitigate the chance of concussion or serious head / brain injuries.”

“The need to mitigate the risk of concussion or more serious head/brain injuries remains a high priority for Leatt,” he adds. “As cost is not LEATT’s main USP, we are able to constantly evaluate different technologies to help us reduce rotational energy (angular velocity) and rotational forces (from angular acceleration) during impact. We have invested in state of the art equipment to help us develop and improve our technology and our latest helmet rig allows us to evaluate linear and rotational impacts at both repetitive load speeds as well as high speed impacts and is the same specification used by the FIM for their new Racing Homologation Programme for helmets.”

The most recent addition to this new sphere of the market was Fly Racing who raised eyebrows with their ‘Formula’ helmet and the Adaptive Impact System formed from energy cells made by Rheon (an ‘active’ strain-rate sensitive material that dissipates energy) and the Conehead liner formation. Fly are perhaps more renowned for their wide catalogue of motorcycling wares and poplar off-road gear lines but Creative Director and a lead figure on the Formula, Jerry Lathrop, emphasises that “FLY Racing has been specializing in helmets and safety gear development for over 20 years. As a gear brand, it is common that our expertise in helmets is a bit overlooked, but it is a very big part of what we do at our headquarters in Boise, Idaho.”

“We have aligned with Dr. Dan Plant and his London based team, Rheon Labs, which are leading the study and development space of impact and rotational materials,” he explains. “We are in the best position we have ever been to effect change in helmet safety. Today, we build the best helmet you can buy for motocross with real and fair benchmark test data available for the world to dig in in and learn all about it. The investment to realize all this was for sure a high cost, in fact the Formula helmet was the most expensive product FLY Racing has ever developed. For test comparisons, we invested in over $30,000 worth of competitor benchmark helmets alone. Our team spent 3 years heavily focused on the project.’

After their renewed dive bomb into the helmet segment Lathrop says that protective capabilities are now priority number one. ‘Most of the helmet developers I have talked with agree that it is time for the helmet standards to implement a rotational impact criterion. For that we are happy to see this type of standard moving forward. As with any safety test methodology, implementation is time consuming and requires a high level of scrutiny and review.’

Alpinestars entered the helmet fray after almost half a decade of refining their SM-8 and SM-10. Safety, characteristically, was at the top of the design brief. “Alpinestars has approached the development of helmet technology in the same way as all other market leading innovations it has brought to the motorcycling and motorsports world over the last 55 years,” the firm said to us of the models that boast MIPS and a number of other features, in particular rigid shell construction. “In the case of the Supertech range of motocross helmets, this has meant four years of focused endeavour before the helmet appeared at Round 1 of the AMA Supercross series in 2018.”

The Italians did admit however that the strides of their newfound helmet peers were not an instigating factor. “The criteria that Alpinestars set for its Supertech helmets are defined by its own long-held beliefs about the needs of riding motorcycles to the limit and the key features that make riding the great experience that riders seek when getting out on their bikes. These criteria are not influenced by other manufacturers products or trends in the market but are shaped by the vision that Alpinestars Product Development Department has for the evolving needs of riders. Homologation standards are an important component in giving a baseline guide for performance but do not define the ultimate product performance or benefits.”

Unfortunately past experience in trying to contact Bell’s marketing team have proven fruitless, so their fascintating Flex technology (which 6D concede holds decent merit) remains on the periphery of this story.

Two of the most recognisable helmet names, Arai and Shoei, felt unwilling or unprepared to vocalise on FRHPhe, which could be expected if the companies are in the throes of testing their own new theories due for release soon (or they may be frantically trying to modernise). ‘The Arai team is in the process of crafting a statement regarding the FIM and the Racing Homologation Program,’ was one response, while Shoei would simply state: ‘We, SHOEI, are not in a position to comment on the homologation. We are developing and manufacturing our products which are complied with the required homologation.’

“The process of implementing the standard has been long and sometimes tough,” admits Manfredi. “Nevertheless the more motivated manufacturers drove the others and everybody is now on the same page. Today, the FIM Helmet Standard is considered worldwide as very advanced and many other standards, institutions, etc. are adopting or adapting the key aspects of it. The FIM Helmet Standard has a solid scientific basis and has been presented, discussed and approved in the most important forums and events, with the biggest worldwide experts in helmet testing and in head injury biomechanics.”

The FIM are conscious that any guideline with such wide-ranging influence has to be watertight and pay total due diligence to an industry that invests millions and millions in R&D and production. Their dependence and trust on existing research and the scientific findings is illustrated by the (so far) ‘cool’ approach to something like neck protection: a device and theory that has seen a number of firms investigate and ultimately manufacture since Leatt presented their case in the middle of the last decade. “The FIM has so far quite neutral (neither recommending them/making them mandatory, nor banning their use),” says Manfredi on the subject of neck braces. “This is due to divergent opinions in the medical and scientific community. So for the moment these are not included in the FRHP and more research is needed going forward.”

‘We are in constant communication with them to ensure that we stay on top of this possible new standard development for the off-road market,’ says Chris Leatt on the subject of FRHPhe. “There are also several other working groups, linked to regulating bodies and organizations (involved with helmet test standards), that are actively discussing the effects of rotational impacts and ways to incorporate them into existing helmet standards. At Leatt Corporation we are constantly innovating and looking at new ways, be it new materials, clever application of existing materials or smart designs, to try and improve the impact protection levels for all the helmets in our product line.”

“The FIM Helmet Standard criteria and thresholds are based on data and findings drawn from internationally recognised scientific publications and works,” Manfredi further justifies. “These references were taken into account in order to select suitable injury criteria and limits related to determined and quantified injury risks.”

But the very nature of a motorcycle crash involves a dizzying array of possibilities and scenarios and that feeds into the complexity of the trials. It is far from simple. “The testing method that is being used, and the testing apparatus for the rotational testing, may require a new approach in the future to help eliminate the inherent variables that are present during rotational testing,” says Weber. “These are due to complicated physics issues that have been studied for many years, and argued from many different groups of people and universities, and need to be developed further to allow for more repeatable test data outcomes by different testing labs. In addition, the injury metrics that are to be used are still in a state of debate from industry experts in the field of biomechanics, the equations used and the weighting as to what is most important for protection. With all this, the FIM has had a tough job in getting the first rotational test standard up and running that the industry helmets can be compared to as a starting point.’

Of course FRHPhe only carries ramifications for companies that showcase and use racing as a research and development test bed. Countless other helmets pass the international tests (DOT, Snell and ECE) for the safety sticker and never see the expanses of a racetrack. This does not stop the FIM believing that FRHPhe could be a watermark. Manfredi: “As the latest state of art methods of testing (such as the innovative oblique test, and linear tests at higher and lower speeds) were included in the Standard, the FIM is hopeful that the Standard will serve as an inspiration for and cascade to international standards for road use. This would be confirmation that we have done a good job and we would be very happy to see safety on the road benefit from our work.”

‘As the leading authoritative body within the motorcycle industry, the FIM has taken a proactive and bold stance to be the first to say we can demand more safety for the riders, and not leave it entirely up to the governments of the world,’ says Weber. ‘It is not easy to get an industry to change its methods and there is an associative cost to not only the manufacturers, but also to the consumers as a whole, and the FIM has tried hard to understand these issues with a balanced approach over an iron fist.’

‘While the FIM has a good start, one of the dangers is that the FRHPhe does not get the needed consumer attention and support, and starts to become less of a concern and the future advancements for more stringent requirements are implemented,” Weber adds. “It will take a lot of ongoing effort and expense for the industry to continue to push the safety requirements to new levels, and as helmet manufacturers we need to be pushing side by side with the FIM to meet these new requirements as they are defined. ‘

Alpinestars, a brand that bases so much of their product development in their comprehensive racing programme, sees the immediate correlation value of FRHPhe. “Racing offers the most demanding test environment for new product technology and also gives the strongest possible assurance of protection standards,” they said to us. “Top level racing is uniquely demanding and not only are minimum safety standards a vital development for rider well-being but also provide a visible and formally established protocol that ensures all equipment being brought to racing is produced to a suitably high standard. These standards, by extension, provide a directly relevant homologation requirement for customers using the technology for their own leisure riding and racing.’

Thanks to FRHPhe racers will soon not have much of a choice but Fly are quick to point out for all the stress and toil towards improvement consumers will make their own minds up about what degree of protection they will prefer. Much in the same way how some people will ride motorcycles wearing shorts and trainers instead of leather trousers and reinforced boots and how some bikers around the world still don’t advocate the use of crash helmets at all. ‘I think there are all levels of need out there,’ says Lathrop. ‘Not everyone can afford the latest technology, nor does everyone follow these technologies. For that reason, some price point products should exist so all can afford to protect themselves. Today’s standards such as DOT and ECE serve a huge role in saving lives every day.’

Leatt says his peers should not cower from what the FIM are proposing and pushing. “As long as the standards are well conceived and applied, no manufacturer should balk at meeting them. Customers demand cool helmets that are protective, manufacturers have an ethical obligation to produce the safest helmets practicable.”

FRHPhe is here to stay and the influence in MotoGP and circuit racing has caused consternation with a delay from February 2019 (and the start of the season) until June 2019 for the enforcement of the homologated models with just AGV, Bell, HJC, Kabuto, X-Lite Nolan, Shark and Shoei’s X-Fourteen receiving the blue stamp so far. Companies that did not submit their lids for laboratory testing before the end of February could miss the test and approval window for ’19. From the start of 2020 FRHPhe homologation will be mandatory.

Elsewhere airbags are now obligatory in MotoGP and it seems with each passing season the FIM are including more and more safety measures into their disciplines; MXGP will soon enforce goggle use on track.

FRHP is the vanguard for more development work that won’t only involve helmets. “The FIM Racing Homologation Programme has been established with this very purpose in mind: a framework to grant special recognition to all products related to safety and as a requirement for FIM competitions,” offers Manfredi. “The main aim of this Programme is to meet the need for an advanced evaluation of the safety performance of different kind of products: among the items under the recent spotlight are off-road helmets, racetrack paints and protective barriers for tracks. There is a lot of work to do with a twofold objective: safe venues and safety for riders.”

By Adam Wheeler @ontrackoffroad

6D Helmets photos by Ray Archer